Navigate:

Project Owner: Graham

Completed: December 2008

An update is long overdue, so here it is.

Firstly we had a few mechanical issues to overcome. Although I had the controller electronics up and running, it was time to build it into the designated enclosure, IE a conventional plastic housing. The hole cutting, heatsink fabrication and final assembly took (not unsurprisingly) more time than expected. After about 2 weeks, putting a few hours in here and there saw a finished controller.

I acquired a membrane keypad from an old motor speed control and used this, as it had integrated tactile switches which I rewired to my internal switches. This worked very well.

For the bicycle I used a second hand frame and replaced the front wheel with my new-and-improved hub motorised wheel. Unfortunately the standard mechanical assembly of the front forks was not capable of putting up with the torsional twisting force exerted by the motor axle. After a few short runs along the road outside our workplace, the axle twisted itself free and splayed the fork aperture open. The wheel (fortunately!) did not come adrift, however some minor damage was incurred by the smaller (hall effect pickup) wires. The controller protection was good in that it kicked in quickly as soon as it detected a (hall sensor) fault, and inhibited any further torque being applied by the motor thus preventing any serious damage.

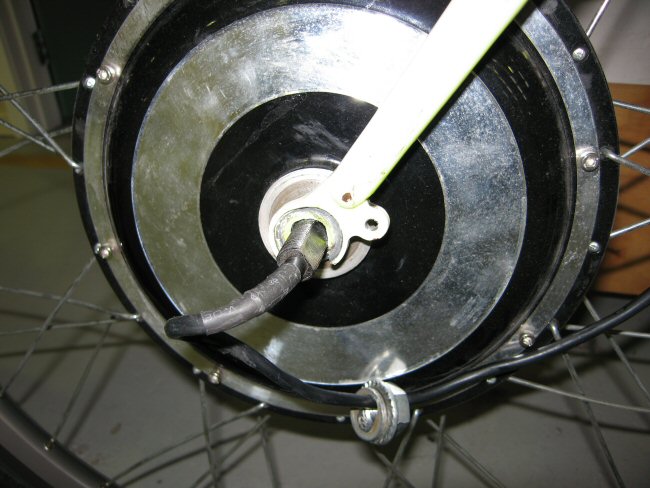

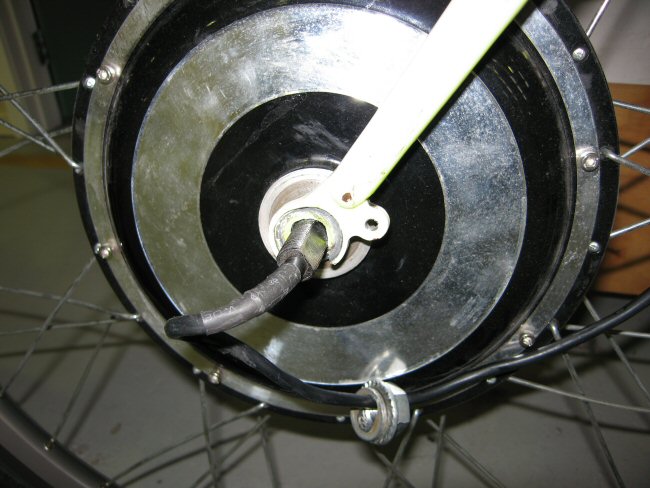

For me it was back to the drawing board. This quickly ramped up to a team effort involving several people at work who were quick to offer advice on eliminating the problem. A workable solution was found and our master welder (thanks Trident!) got stuck in and reinforced the forks for me. I fabricated a pair of torsion bars using some steel bars from work for extra axle keying ability. The final assembly can be seen below and has worked very well indeed.

Well with much prompting at work it was time for an on-street demonstration. As our crash test dummy has since left us for Switzerland, I was forced to resort to testing my own product! No volunteers to ride the machine, however many cameramen were in evidence to catch any potential "incidences" on camera. However anyone secretly hoping to catch that "shot-in-a-million" were proven disappointed as the bike performed very well (if I do say so myself) with a number of rides up and down the road. Top speed achieved was about 58km/h. See the video below as well.

Since the inaugural ride about 3 months ago, I have ridden nearly 1000km's with only a few minor problems. The batteries are the worst culprit here, however that said I am using secondhand sealed lead acids and pushing them to more than 4C, or about 20A continuous when riding at top speed or accelerating. The only failure with regard to the controller has been a track burnout on the board (I overlooked beefing up the copper trace with solder before assembly).

My next project is an electric motorbike, also with a hub motor. I have opted not to proceed further with the second motor on the bicycle as I have learned about as much as I am going to from this project and the batteries would simply not be up to the task of handling 2 motors! The electric motorbike lends itself to considerably more battery capacity but that is another story to come in due course...

Beginning of electric bike project

Firstly we had a few mechanical issues to overcome. Although I had the controller electronics up and running, it was time to build it into the designated enclosure, IE a conventional plastic housing. The hole cutting, heatsink fabrication and final assembly took (not unsurprisingly) more time than expected. After about 2 weeks, putting a few hours in here and there saw a finished controller.

I acquired a membrane keypad from an old motor speed control and used this, as it had integrated tactile switches which I rewired to my internal switches. This worked very well.

For the bicycle I used a second hand frame and replaced the front wheel with my new-and-improved hub motorised wheel. Unfortunately the standard mechanical assembly of the front forks was not capable of putting up with the torsional twisting force exerted by the motor axle. After a few short runs along the road outside our workplace, the axle twisted itself free and splayed the fork aperture open. The wheel (fortunately!) did not come adrift, however some minor damage was incurred by the smaller (hall effect pickup) wires. The controller protection was good in that it kicked in quickly as soon as it detected a (hall sensor) fault, and inhibited any further torque being applied by the motor thus preventing any serious damage.

For me it was back to the drawing board. This quickly ramped up to a team effort involving several people at work who were quick to offer advice on eliminating the problem. A workable solution was found and our master welder (thanks Trident!) got stuck in and reinforced the forks for me. I fabricated a pair of torsion bars using some steel bars from work for extra axle keying ability. The final assembly can be seen below and has worked very well indeed.

Well with much prompting at work it was time for an on-street demonstration. As our crash test dummy has since left us for Switzerland, I was forced to resort to testing my own product! No volunteers to ride the machine, however many cameramen were in evidence to catch any potential "incidences" on camera. However anyone secretly hoping to catch that "shot-in-a-million" were proven disappointed as the bike performed very well (if I do say so myself) with a number of rides up and down the road. Top speed achieved was about 58km/h. See the video below as well.

Since the inaugural ride about 3 months ago, I have ridden nearly 1000km's with only a few minor problems. The batteries are the worst culprit here, however that said I am using secondhand sealed lead acids and pushing them to more than 4C, or about 20A continuous when riding at top speed or accelerating. The only failure with regard to the controller has been a track burnout on the board (I overlooked beefing up the copper trace with solder before assembly).

My next project is an electric motorbike, also with a hub motor. I have opted not to proceed further with the second motor on the bicycle as I have learned about as much as I am going to from this project and the batteries would simply not be up to the task of handling 2 motors! The electric motorbike lends itself to considerably more battery capacity but that is another story to come in due course...

Beginning of electric bike project

This project has been viewed 6440 times.